Imikhiqizo

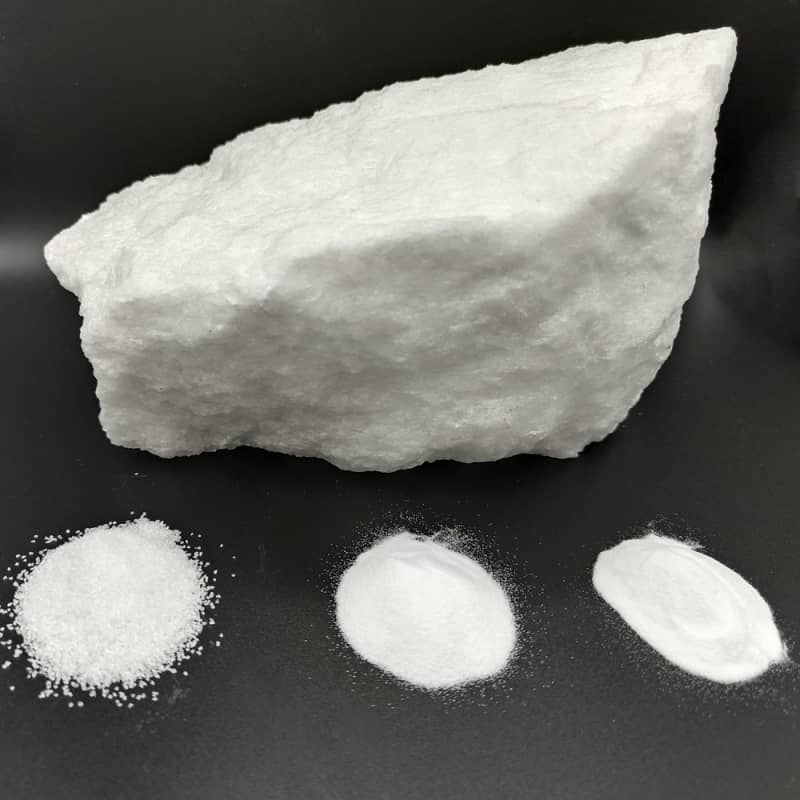

I-Abrasive Material White Fused Alumina Grits

I-alumina ehlanganisiwe emhlophe iyimpuphu ye-alumina njengempahla eluhlaza, ehlala ingaphezulu kuka-2000 ℃ izinga lokushisa eliphezulu elincibilikisa isithando somlilo se-arc kagesi, ngemva kokuphihliza ipulasitiki, ukuhlukaniswa kazibuthe kunsimbi, isikrini sihlukaniswe ngezinhlobonhlobo zosayizi wezinhlayiyana, ukuthungwa okuminyene, ubulukhuni obuphezulu, ifomu eliyimbudumbudu Ukuqina kwe-Angle. iphakeme kune-alumina ensundu ehlanganisiwe incane, ukuqina okuphansi kancane, amandla okusika aqinile nokuzinza kwamakhemikhali kuhle, inokwahlukanisa okuhle kakhulu.

I-alumina ehlanganisiwe emhlophe yenziwe nge-high-purity low-sodium alumina powder ngokuncibilika ezingeni lokushisa eliphezulu, ukupholisa icrystallization, bese iyachoboza.Igrit ye-alumina emhlophe ehlanganisiwe ingaphansi kolawulo oluqinile ukuze kugcinwe ukusatshalaliswa kosayizi wokusanhlamvu nokubukeka okungaguquki.

Okuvame ukusetshenziswa kuma-ladle castables, izinto zokugijima zensimbi, izinto ezixubene nesibhamu esiphikisayo neminye imikhiqizo ye-monolithic refractory;

Okwezinto ezibunjiwe eziphikisayo, isetshenziswa kakhulu ezintweni ezingavuthiwe ezisezingeni eliphakeme zesitini se-corundum, i-corundum mullite, isitini sepulaki esicwengekile sensimbi, isibhamu se-spray esibalulekile, i-steelmaking kanye nemboni yokuphonsa eqhubekayo.

Ingasetshenziswa futhi njengezinto zokupholisha, ukuphonsa ngokunemba, ukufutha nokumboza, izitsha zobumba ezikhethekile

Okumhlophe, i-crystal α ngaphezu kuka-99%, ukuhlanzeka okuphezulu, ubulukhuni obuphezulu, nokuqina okuphezulu, amandla okusika aqinile, ukuqina kwamakhemikhali okuqinile, nokufakwa okuqinile.

| Mohs ubulukhuni | 9 |

| Ukuminyana ngobuningi | 1.75-1.95g/cm3 |

| Amandla adonsela phansi athize | 3.95g/cm3 |

| Ukuminyana kwevolumu | 3.6 |

| Idigri yokuncibilika | 2250 ℃ |

| Idigri ye-Refractory | 2000 ℃ |

Isetshenziselwa refractory, castable

| Izakhiwo | 0-1 1-3 3-5m/m | F100 F200 F325 | |||

| Isiqinisekiso Inani | Inani Elijwayelekile | Isiqinisekiso Inani | Inani Elijwayelekile | ||

| Ukwakheka Kwamakhemikhali | I-Al2O3 | ≥99.1 | 99.5 | ≥98.5 | 99 |

| SiO2 | ≤0.4 | 0.06 | ≤0.30 | 0.08 | |

| Fe2O3 | ≤0.2 | 0.04 | ≤0.20 | 0.1 | |

| Na2O | ≤0.4 | 0.3 | ≤0.40 | 0.35 | |

Isetshenziselwa ama-abrasives, ukuqhumisa, ukugaya

| Uhlobo Lwezakhiwo | Okusanhlamvu | ||

| 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | |||

| Isiqinisekiso Inani | Inani Elijwayelekile | ||

| Ukwakheka Kwamakhemikhali | I-Al2O3 | ≥99.1 | 99.5 |

| SiO2 | ≤0.2 | 0.04 | |

| Fe2O3 | ≤0.2 | 0.03 | |

| Na2O | ≤0.30 | 0.2 | |

Isetshenziselwa abrasives, lapping, polishing

| Uhlobo Lwezakhiwo | I-Micropowder | |||

| “W” | W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 | |||

| "FEPA" | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 | |||

| "JIS" | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000#0600#120# 120 | |||

| Isiqinisekiso Inani | Inani Elijwayelekile | |||

| Ukwakheka Kwamakhemikhali | I-Al2O3 | ≥99.1 | 99.3 | |

| SiO2 | ≤0.4 | 0.08 | ||

| Fe2O3 | ≤0.2 | 0.03 | ||

| Na2O | ≤0.4 | 0.25 | ||

1.Awekho amathonya mayelana nombala wezingxenye ezicutshunguliwe.

I-2.Ingasetshenziswa ezinkambisweni lapho insalela ye-iron powder ivinjelwe ngokuqinile.

3.Izinhlamvu zokubumba zifaneleka kakhulu ekusebenzeni kwe-sandblasting emanzi kanye nokupholisha.

1.Ukuqhunyiswa kwesihlabathi, ukupholishwa nokugaya insimbi nengilazi.

2.Ukugcwalisa upende, ukunamathela okungagugi, i-ceramic, ne-glaze.

3.Ukwenziwa kwesondo lokugaya, i-sandpaper nendwangu ye-emery.

I-4.Ukukhiqizwa kolwelwesi lwe-ceramic filter, amashubhu e-ceramic, amapuleti e-ceramic.

5.Ngokusetshenziswa kwesitezi esingagugi.

6.Ukuqhunyiswa kwesihlabathi kwamabhodi esekethe.

7.Ukuqhunyiswa kwesihlabathi kwemikhumbi, izinjini zezindiza, amathrekhi esitimela nemizimba yangaphandle.

8.Various white fused aluminium oxide okusanhlamvu ingakhiqizwa ngokuvumelana nezidingo ezahlukene amakhasimende.

Umbuzo Wakho

Uma unemibuzo.Sicela ukhululeke ukusithinta.