Imikhiqizo

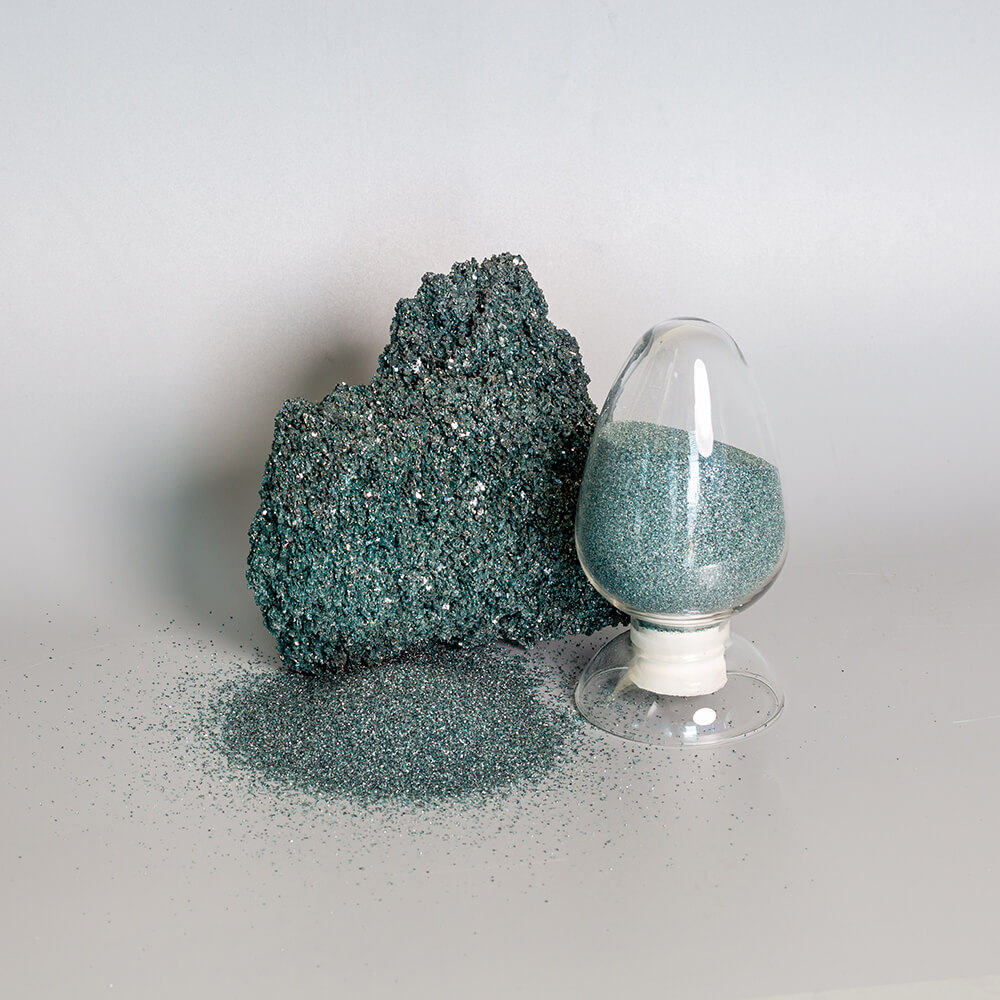

I-Green Silicon Carbide Powder ye-Bonded Silicon Carbide Isondo Lokugaya

Incazelo ye-silicon carbide eluhlaza

I-silicon carbide eluhlaza yenziwe ngesihlabathi se-quartz ne-petroleum coke ngokusebenzisa ukuncibilika okuphezulu kwezinga lokushisa. Indlela yokukhiqiza iyafana naleyo ye-silicon carbide emnyama, kodwa izidingo zezinto ezingavuthiwe zihlukile. Amakristalu ancibilikisiwe anobumsulwa obuphezulu, ubulukhuni obuphezulu namandla okusika aqinile, futhi afaneleka ukucubungula izinto eziqinile neziphukayo. I-silicon carbide eluhlaza ilungele ukugaya ama-alloys aqinile, izinsimbi eziqinile neziphukayo kanye nezinto ezingezona ezensimbi, njengezinsimbi ezingenayo insimbi njengethusi, ithusi, i-aluminium ne-magnesium, nezinto ezingezona ezensimbi njengamatshe ayigugu, ingilazi yokukhanya nezitsha zobumba.

| Izakhiwo Zemvelo | |

| Umbala | Okuhlaza |

| Ifomu le-Crystal | Ipholigoni |

| Mohs ubulukhuni | 9.2-9.6 |

| Ubulukhuni obuncane | 2840~3320kg/mm² |

| Iphoyinti lokuncibilika | 1723 |

| Izinga lokushisa eliphezulu lokusebenza | 1600 |

| Ukuminyana kwangempela | 3.21g/cm³ |

| Ukuminyana ngobuningi | 2.30g/cm³ |

| Ukwakheka kwamakhemikhali | |||

| Okusanhlamvu | Ukwakheka kwamakhemikhali(%) | ||

| Sic | FC | Fe2O3 | |

| 16#--220# | ≥99.0 | ≤0.30 | ≤0.20 |

| 240#--2000# | ≥98.5 | ≤0.50 | ≤0.30 |

| 2500#--4000# | ≥98.5 | ≤0.80 | ≤0.50 |

| 6000#-12500# | ≥98.1 | ≤0.60 | ≤0.60 |

1.I-Abrasive: imoto, i-aerospace, i-metalworking, nobucwebe. Isetshenziselwa ukugaya, ukusika, nokupholisha izinsimbi eziqinile nezitsha zobumba.

I-2.I-Refractory: ama-furnaces nama-kilns ngenxa ye-conductivity yayo ephezulu yokushisa kanye nokwanda okuphansi kokushisa.

3.Ama-elekthronikhi: Ama-LED, izisetshenziswa zamandla, kanye nemishini ye-microwave ngenxa ye-conductivity yayo kagesi enhle kakhulu kanye nokuzinza kwe-thermal.

4.Amandla elanga: amaphaneli elanga

5.Insimbi

I-6.I-Ceramics: amathuluzi okusika, izingxenye ezingagqoki, kanye nezingxenye zokushisa okuphezulu

Umbuzo Wakho

Uma unemibuzo.Sicela ukhululeke ukusithinta.