Imikhiqizo

UPlatelet wabhalela i-alumina i-powder

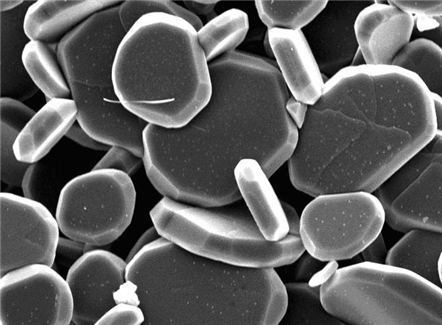

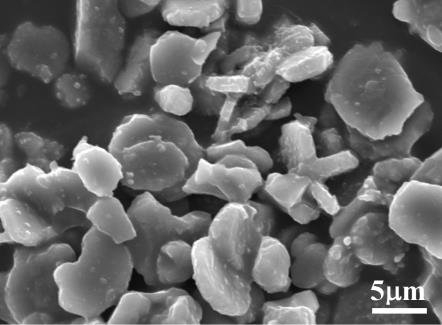

I-Plate Calcined Alumina polishing powder yenziwe nge-alumina powder yezinga eliphezulu njengempahla eluhlaza, futhi icutshungulwe ngenqubo yokukhiqiza ekhethekile. Umumo wekristalu wempushana yokupholisha i-alumina ekhiqiziwe iyi-hexagonal flat efana ne-tabular shape, ngakho ibizwa ngokuthi i-Platelet Alumina noma i-Tabular Alumina.

I-Platelet Alumina iwuhlobo oluphezulu lwe-alumina impushana ehuqayo, ehlanganisa ikristalu emise okwepuleti ye-Al2O3 enobumsulwa obungaphezu kuka-99.0%. Inezici ezinhle kakhulu zokumelana nokushisa kanye nokungangenisi amakhemikhali, futhi ayigqwali ngama-asidi noma ama-alkaline. Njengoba ukusatshalaliswa kosayizi wezinhlayiyana ze-Platelet Alumina kulawulwa ngokuqinile, kungakhiqiza indawo enhle kakhulu enamasondo, inikeze ukusebenza kahle okuphakeme njengento eqhumayo. Ngohlu olukhulu lwezinto ezisetshenziswayo, i-Platelet Alumina iyimpushana ehuqayo ekwazi ukwenza inqwaba yemisebenzi.

Tabular alumina powder

Tabular alumina powder

Ukucaciswa okujwayelekile kobukhulu bezinhlayiyana

| Izinhlayiya | Ukusatshalaliswa kwezinhlayiyana (μm) | |||

| Izinhlayiya eziphezulu | Usayizi wezinhlayiya | Usayizi wezinhlayiya | Usayizi wezinhlayiya | |

| 45 | <82.9 | 53.4± 3.2 | 34.9± 2.3 | 22.8± 1.8 |

| 40 | <77.8 | 41.8± 2.8 | 29.7± 2.0 | 19.0± 1.0 |

| 35 | <64.0 | 37.6± 2.2 | 25.5± 1.7 | 16.0± 1.0 |

| 30 | <50.8 | 30.2± 2.1 | 20.8± 1.5 | 14.5± 1.1 |

| 25 | <40.3 | 26.3± 1.9 | 17.4± 1.3 | 10.4± 0.8 |

| 20 | <32.0 | 22.5± 1.6 | 14.2± 1.1 | 9.00±0.80 |

| 15 | <25.4 | 16.0± 1.2 | 10.2± 0.8 | 6.30±0.50 |

| 12 | <20.2 | 12.8± 1.0 | 8.20±0.60 | 4.90±0.40 |

| 9 | <16.0 | 9.70±0.80 | 6.40±0.50 | 3.60±0.30 |

| 5 | <12.7 | 7.20±0.60 | 4.70±0.40 | 2.80±0.25 |

| 3 | <10.1 | 5.20±0.40 | 3.10±0.30 | 1.80±0.30 |

Izinga Lekhwalithi

| Uhlobo lomkhiqizo | I-Gravity ethize | ||||

| I-Al2O3 | SiO2 | Fe2O3 | Na2O | ||

| 3µm-45µm | 3.90 | >99.0 | <0.20 | <0.10 | <1.00

|

Izinzuzo ze-Alumina Powder

1. Qhathanisa nenye impushana yethebula, i-tabular alumina powder inezakhiwo ezinhle kakhulu zokuhlanganisa. Njengephuzu elincibilikayo eliphezulu, ubulukhuni obuqinile, amandla aphezulu emishini, ukumelana nokugqokwa okuhle, ukumelana namakhemikhali, ukumelana ne-oxidation nokumelana nokushisa njll.

2. Ukuma kweshidi eliyisicaba kwenza ukungqubuzana kube kukhudlwana, kuthuthukisa isivinini sokugaya nokusebenza kahle, lokhu kunganciphisa inani lemishini yokugaya, umsebenzi kanye nesikhathi sokugaya.

3. Ukuma kweshidi eliyisicaba kwenza into igaye kungabi lula ukuyiklwebha, izinga lemikhiqizo efanelekile lingakhuphuka ngo-10% -15%. Isibonelo, izinga le-semiconductor silicon wafer efanelekayo lingafinyelela ku-96% noma ngaphezulu.

4. Inemiphumela ephindwe kabili ye-nano kanye ne-micro powders, umsebenzi ongaphezulu uphakathi, awukwazi nje ukuhlanganisa ngokuphumelelayo namanye amaqembu asebenzayo, kodwa futhi akulula ukuhlanganisa nokwenza lula ukuhlakazeka okuphumelelayo.

5. Inonamathela kahle, umphumela obalulekile wokuvikela kanye nekhono lokukhombisa ukukhanya.

6. I-alumina ye-tabular powder icishe ibe sobala, ayinambala, futhi inendawo eyisicaba futhi ebushelelezi. Amakristalu acwebezeliswe kahle angamahexagon avamile.

7. I-alumina ye-tabular powder ingenziwa ibe yimpushana enhle kakhulu yokupholisha.

1. Imboni yezogesi: ukugaya nokupholishwa kwamawafa e-silicon e-semiconductor monocrystalline, amakristalu equartz quartz, ama-semiconductors ayinhlanganisela (crystalline gallium, phosphating nano).

2. Imboni yengilazi: ukugaya nokucutshungulwa kwekristalu, ingilazi yequartz, isikrini segobolondo lengilazi ye-kinescope, ingilazi ebonakalayo, i-liquid crystal display (LCD) yengilazi engaphansi, nekristalu ye-quartz.

3. Imboni yokugqoka: izigqoko ezikhethekile nezigcwalisi zokufafaza i-plasma.

4. Imboni yokucubungula insimbi ne-ceramic: izinto zokwakha ze-ceramic ezinembile, izinto zokusetshenziswa kwe-ceramic e-sintered, i-high-grade high-temperature coatings, njll.

Umbuzo Wakho

Uma unemibuzo.Sicela ukhululeke ukusithinta.