Imikhiqizo

I-Metal abrasive Steel Grit Blast Media

IZIBONGO ZESIZINI

Le mithombo yezindaba enolaka isetshenziswa ekuqhumeni nasekukhumuleni insimbi nezinsimbi. I-Steel Grit ikhiqiza ngempumelelo ukunamathisela ezinsimbini eziqinile ukuze kunamathele kangcono okokunamathela okuhlanganisa upende, i-epoxy, koqweqwe lwawo kanye nerabha. Okusetshenziswayo kuhlanganisa ukulungisa kabusha imoto yesitimela, ukususwa kokucwayiza, amabhuloho aqhumayo, izingxenye zensimbi kanye nezicelo zemboni yokubumba.

| Imikhiqizo | Igrithi Yensimbi | |

| Ukwakheka Kwamakhemikhali | CR | 1.0-1.5% |

| C | 1.0-1.5% | |

| Si | 0.4-1.2% | |

| Mn | 0.6-1.2% | |

| S | ≤0.05% | |

| P | ≤0.05% | |

| Ukuqina | Isibhamu sensimbi | I-GP 41-50HRC;GL 50-55HRC;GH 63-68HRC |

| Ukuminyana | Isibhamu sensimbi | 7.6g/cm3 |

| Isakhiwo esincane | Isakhiwo se-Martensite | |

| Ukubukeka | Izinhlayiya Eziyizigodi Eziyisiyingi<5% Izinhlayiya Zokuqhekeka<3% | |

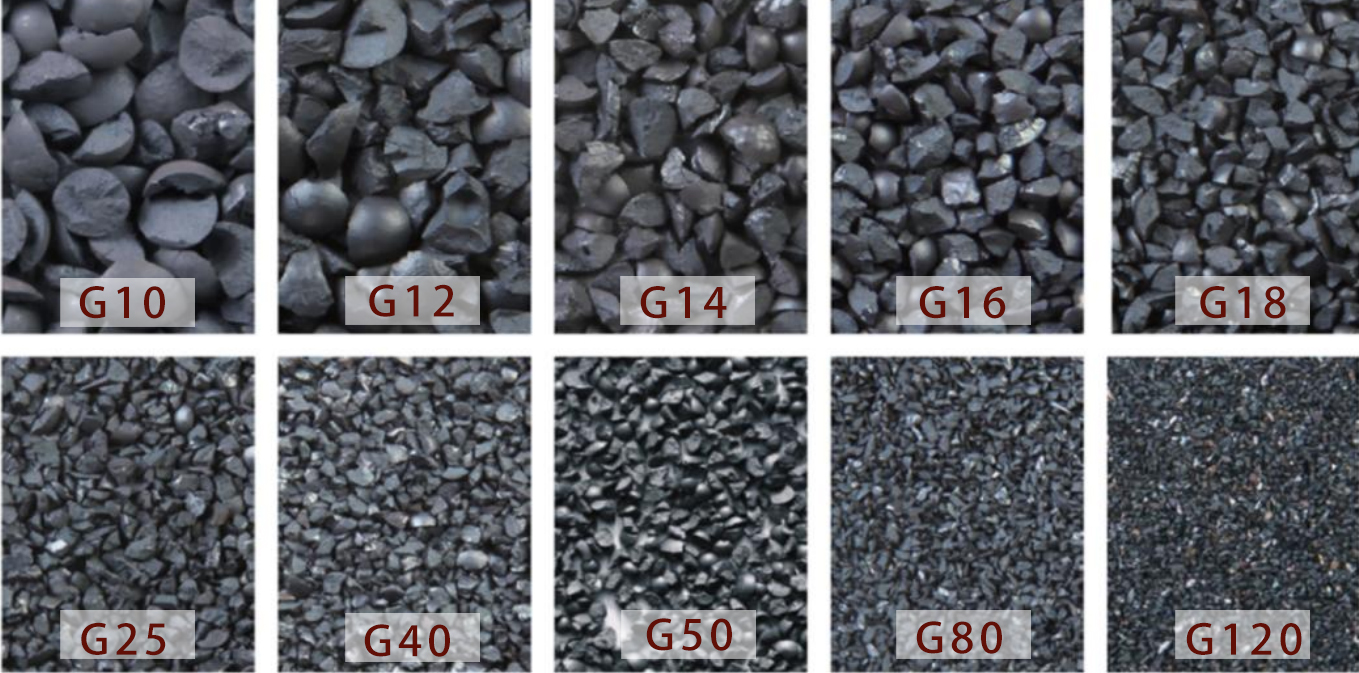

| Uhlobo | I-G120,G80,G50,G40,G25,G18,G16,G14,G12,G10 | |

| Ububanzi | 0.2mm, 0.3mm,0.5mm,0.7mm,1.0mm,1.2mm,1.4mm,1.6mm,2.0mm,2.5mm | |

Isicelo se-Steel Grit

1.Ukulungiswa kwendawo: Izinsimbi zensimbi zisetshenziselwa kakhulu ukulungiswa kwendawo ngaphambi kokufaka izimbotshana, amapende, noma izinto zokunamathisela. Basusa ngokuphumelelayo ukugqwala, isikali, izambatho ezindala, nokungcola okuvela ezindaweni zensimbi, ukuqinisekisa ukunamathela okufanele kwezinto ezilandelayo.

2.Ukugqwala Nokugqwala: Izinsimbi zensimbi zisetshenziselwa ukususa ukugqwala okukhulu, ukugqwala, nesikali sokugaya endaweni yensimbi, ikakhulukazi ezimbonini ezifana nokwakha umkhumbi, ukunakekela olwandle, kanye nokwakhiwa kwensimbi yesakhiwo.

I-3.Ukulungiselela i-Welding: Ngaphambi kwe-welding noma ezinye izinqubo zokujoyina, ama-grits ensimbi angasetshenziswa ukuhlanza nokulungisa izindawo ezingaphezulu, ukuqinisekisa ukuhlangana okuqinile nokuhlanzekile kwe-weld.

4.Ukulungiswa Komphezulu Wokhonkolo kanye Netshe: Izinsimbi zensimbi zingasetshenziselwa ukuhlanza nokulungisa izindawo ezikhonkolo nezingamatshe, njengamaphrojekthi okubuyisela, lapho ukususwa kwezimbotshana ezindala, amabala, noma ukungcola kuyadingeka.

5.I-Shot Peening: Ngenkathi amashothi ensimbi esetshenziswa kakhulu ukuchama, ama-grits ensimbi nawo angasetshenziswa kule nqubo. Ukuchama kuhilela ukubhobhoza indawo enezinhlayiya ezilumayo ukuze ubangele ingcindezi ecindezelayo, okuthuthukisa amandla wento kanye nokumelana nokukhathala.

6.I-Deburring and Deflashing: Igrits yensimbi isetshenziselwa ukususa ama-burrs, imiphetho ecijile, nezinto ezidlulele ezingxenyeni zensimbi, ikakhulukazi ezinqubweni zokukhiqiza lapho ukunemba nokushelela kuyadingeka.

Izicelo ze-7.Foundry: Izinsimbi zensimbi zisetshenziselwa ukuhlanza nokulungisa izindawo zokuphonsa, ukususwa kwesikhunta kanye nomgogodla, kanye nokwelashwa kwendawo yonke yensimbi. 8.Iphrofayili Yobuso: Izinsimbi zensimbi zisetshenziselwa ukudala amaphrofayili athile angaphezulu, ikakhulukazi ezimbonini ezifana nezokwakha nezokwakha imikhumbi. Lawa maphrofayili athuthukisa ukunamathela kokunamathela futhi anikeze ukubamba okungcono kwezindawo ezilwa nokushelela.

I-9.I-Stone Cutting and Etching: Ezimbonini zokwakha nezesikhumbuzo, izinsimbi zensimbi zisetshenziselwa ukusika nokufaka amatshe nezinye izinto eziqinile, ukudala imiklamo eyinkimbinkimbi namaphethini.

10.Imboni Kawoyela Negesi: Izinsimbi zensimbi zisetshenziselwa ukulungiswa kwendawo embonini kawoyela negesi, njengokuhlanza amapayipi, amathangi, nezinye izinto zokusebenza.

11.Imboni Yezimoto: Amagridi ensimbi angasetshenziselwa ukukhumula upende namajazi ezingxenyeni zezimoto, ukulungisa izindawo ezizolungiswa kabusha noma zilungiswe.

Kubalulekile ukuqaphela ukuthi ukukhethwa kosayizi ofanelekile wegrit yensimbi, ubulukhuni, nokunye ukucaciswa kuncike ekusetshenzisweni okukhethekile kanye nokuqedwa kwendawo oyithandayo. Izici zokugwaza zensimbi zizenza amathuluzi abalulekile emisebenzi edinga ukususwa kwezinto eziqinile kanye nokulungiswa kwendawo.

Umbuzo Wakho

Uma unemibuzo.Sicela ukhululeke ukusithinta.