Ukukhiqiza Okungeziwe kanye Nokukhiqiza Okukhiphayo: Ingxoxo Ngokusetshenziswa Kwesikhunta Ngemuva Kwemishini Yokunemba

Ukukhiqiza kwezimboni zanamuhla kubeke phambili izidingo eziphakeme zokunemba, ukusebenza kahle kanye nenkululeko yokuklama. Ngokungeziwe kubuchwepheshe bendabuko bokukhiqiza obukhiphayo (njengokugaya, ukugaya, njll.),ukukhiqiza okungeziwe (ukuphrinta kwe-3D)ubuchwepheshe buvela ngokushesha futhi buyindlela ebalulekile yokukhiqiza izinto ezintsha. Zombili zinezinzuzo zazo futhi zisetshenziswa kabanzi emikhakheni yezimoto, i-aerospace, imishini yezokwelapha kanye nokukhiqizwa kwemishini. Kulezi zindlela ezimbili zokukhiqiza, indima yesikhunta ibaluleke kakhulu futhi ihlobene ngokuqondile nekhwalithi yokucubungula nokusebenza kahle kokukhiqiza.

Isingeniso ku-Additive Manufacturing Technology kanye ne-Mold Application

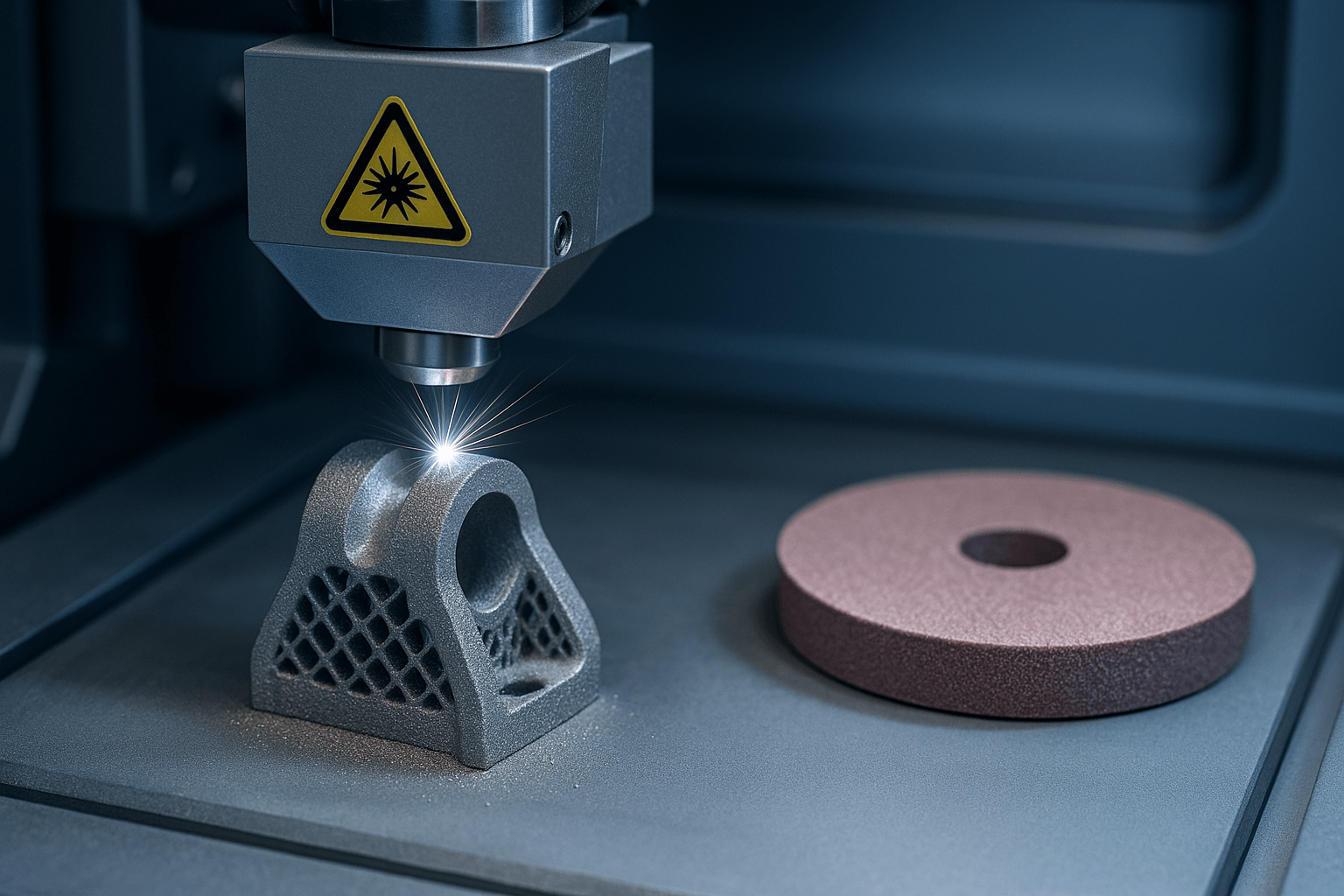

Ukukhiqiza okungeziwe, okwaziwa nangokuthi ukuphrinta kwe-3D, kuyinqubo yokwakha izingxenye ngokunqwabelanisa izinto zokwakha ungqimba ngongqimba. Ubuchwepheshe obujwayelekile bokukhiqiza okungeziwe buhlanganisa i-selective laser sintering (SLS), selective laser melting (SLM), i-fused deposition modeling (FDM) kanye ne-stereolithography (SLA). Lolu hlobo lobuchwepheshe lwaziwa ngenkululeko yalo yokuklama ephezulu kakhulu. Ingakwazi ukwenza izingxenye ezinomumo oyinkimbinkimbi kanye nezimbotshana zangaphakathi noma izakhiwo zegridi, ngokusetshenziswa okuphezulu kwezinto ezibonakalayo futhi yehlise kakhulu udoti wezinto ezibonakalayo. Ukukhiqiza okungeziwe kulungele ikakhulukazi ukwenziwa kwe-prototyping esheshayo, ukukhiqizwa kwenqwaba encane kanye nokwenza ngokwezifiso komuntu siqu, futhi kusetshenziswa kabanzi ku-aerospace, izimoto, imishini yezokwelapha kanye nokukhiqizwa kwesikhunta. Izinzuzo zayo futhi zihlanganisa ukufinyeza umjikelezo wokuthuthukiswa, ukukhuthaza ukwakheka okusha kanye nokugcwaliseka kwezixazululo ezihlukene.

Nakuba ukukhiqiza okungeziwe kungakha ngokuqondile izakhiwo eziyinkimbinkimbi, ingaphezulu lezingxenye eziphrintiwe ngokuvamile lilukhuni, linemigqa yongqimba kanye namaphutha amancane, futhi umshini olandelayo uyadingeka ukuze kuhlangatshezwane nezidingo zezinga eliphezulu. Ngalesi sikhathi, ama-abrasives asebenzayo aba amathuluzi abalulekile. Ama-Abrasives anjaloamasondo okugaya, amabhande esihlabathi, amasondo e-flap kanye namasondo okupholisha asetshenziswa kakhulu ekukhipheni, ukucwenga kwendawo kanye nokuqedwa kwezingxenye zokukhiqiza ezingeziwe ukuze kuqinisekiswe ukuthi imikhiqizo ifinyelela ukunemba kwebanga lezimboni kanye nobuhle. Ikakhulukazi emikhakheni ye-aerospace neyezokwelapha, izimfuneko eziphezulu zekhwalithi engaphezulu nokusebenza ziqhube ama-abrasives ukuthi athuthukise ngokuqhubekayo izinto ezisebenza kahle nezingagqoki ukuze kuhlangatshezwane nezidingo ezikhethekile zokukhiqiza okungeziwe ngemuva kokucubungula.

Isingeniso kubuchwepheshe bokukhiqiza obukhiphayo kanye nokusetshenziswa kwe-abrasive

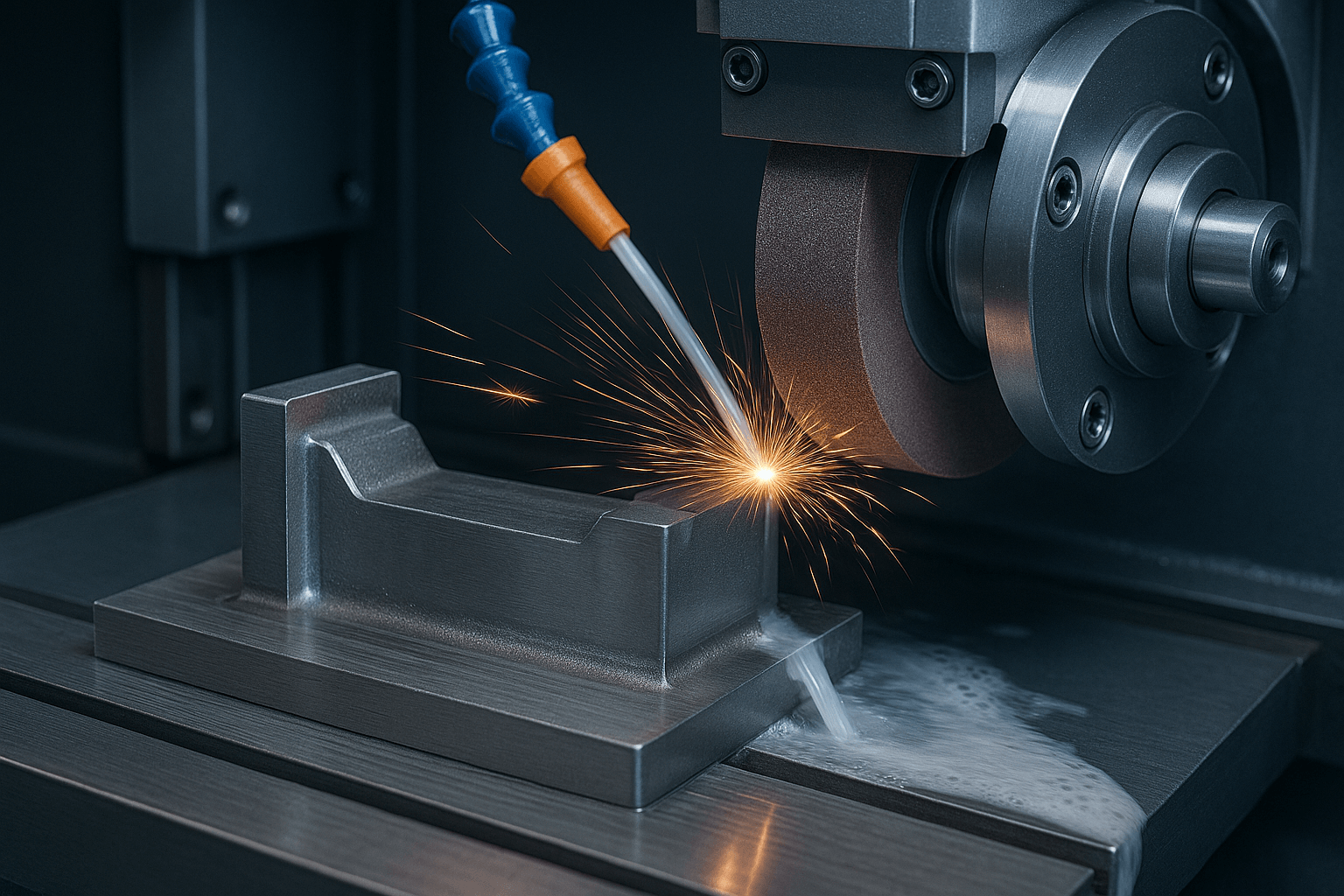

Ukukhiqiza okukhiphayoukususa impahla eningi ngokusika, ukugaya, ukugaya nezinye izindlela zokucubungula ucezu lokusebenza lube yisimo esinqunywe kusengaphambili. Lobu buchwepheshe buvuthiwe futhi bufanele ukukhiqizwa ngobuningi, ikakhulukazi ekuqinisekiseni ubukhulu obunembe kakhulu kanye nekhwalithi ephezulu kakhulu yendawo. Izinqubo ezijwayelekile zifaka ukugaya i-CNC, ukuguqula, ukugaya, ukusika izintambo, umshini wokukhipha ugesi (EDM), ukusika i-laser nokusika indiza yamanzi. Ukukhiqizwa kwe-subtractive kudlala indima ebalulekile ekukhiqizeni izimoto, i-aerospace, ukukhiqizwa kwemishini kanye nemishini yezokwelapha. Ingakwazi ukucubungula kahle insimbi, insimbi yokusansimbi, ama-alloys e-aluminium kanye nezinto eziyinhlanganisela ukuze ihlangabezane nezidingo eziqinile zemboni zokuqina nokusebenza.

Ama-Abrasives adlala indima eyisisekelo nebalulekile ekukhiqizeni okukhiphayo, ikakhulukazi enqubweni yokugaya. Izinhlobo ezahlukene zamasondo okugaya (njengamasondo e-ceramic okugaya, amasondo okugaya ahlanganiswe ne-resin) kanye namathuluzi okupholisha asetshenziswa kakhulu ekwenzeni imishini enzima, ukuqeda kanye nokupholishwa kwendawo ngokwezidingo zenqubo ukuze kuqinisekiswe ukuthi izingxenye zifinyelela ukunemba okuphezulu kanye nekhwalithi yendawo yesibuko. Ukusebenza kwe-abrasive kuthinta ngokuqondile ukusebenza kahle kokucubungula kanye nekhwalithi yomkhiqizo, okugqugquzela ukusungulwa okusha okuqhubekayo kwezinto ezilimazayo nezakhiwo ukuhlangabezana nezidingo zokucubungula zezinto ezinobulukhuni obuphezulu kanye namajiyometri ayinkimbinkimbi.

Njengebhuloho elibalulekile phakathi kwalokhu okubili, ama-abrasives asekela ukuxhumana okungenamthungo kusukela ekukhiqizeni okungeziwe kuya ekukhiqizeni okukhiphayo. Ngokusetshenziswa okwandayo kwezinto eziyinhlanganisela nezinto ezinobulukhuni obuphezulu, ukuthuthukiswa kobuchwepheshe be-abrasive sekuyisixhumanisi esibalulekile ekuqinisekiseni ikhwalithi yokukhiqiza. Ukusabela ezinkingeni zokuqina okungaphezulu kokukhiqizwa okunezinsimbi kanye nezidingo ezinembayo eziphezulu zokukhiqiza okukhiphayo, ucwaningo nokuthuthukiswa kwezikhunta kuyaqhubeka kuthuthukela ekuqineni okuphezulu, ukwakheka okungcono nokuphila isikhathi eside, ukukhuthaza ubuhlakani nokusebenza kahle kwalo lonke uchungechunge lokukhiqiza.