Ukusetshenziswa kwe-α-alumina entshai-alumina ceramics

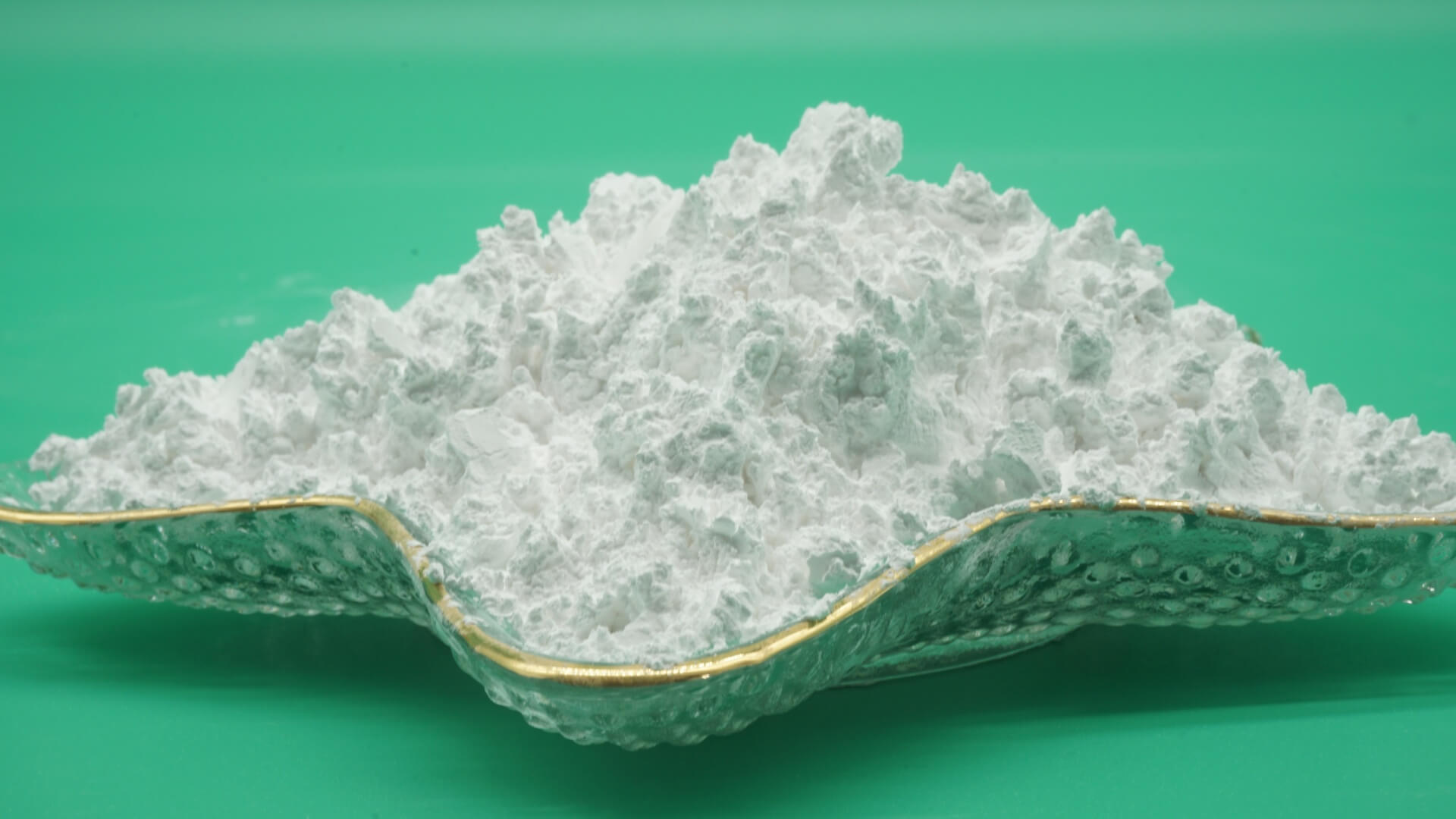

Nakuba kunezinhlobo eziningi zezinto ezintsha ze-ceramic, zingahlukaniswa cishe zibe izigaba ezintathu ngokwemisebenzi yazo kanye nokusetshenziswa kwazo: izitsha zobumba ezisebenzayo (ezaziwa nangokuthi izitsha zobumba zikagesi), izitsha zobumba zesakhiwo (ezaziwa nangokuthi izitsha zobumba zobunjiniyela) kanye ne-bioceramics. Ngokusho kwezingxenye ezihlukene zempahla eluhlaza ezisetshenzisiwe, zingahlukaniswa zibe yi-oxide ceramics, i-nitride ceramics, i-boride ceramics, i-carbide ceramics kanye ne-ceramics yensimbi. Phakathi kwazo, i-alumina ceramics ibaluleke kakhulu, futhi impahla yayo eluhlaza i-α-alumina powder yokucaciswa okuhlukahlukene.

I-α-alumina isetshenziswa kabanzi ekukhiqizeni izinto ezintsha ezihlukahlukene ze-ceramic ngenxa yamandla ayo aphezulu, ubulukhuni obukhulu, ukumelana nokushisa okuphezulu, ukumelana nokugqoka nezinye izakhiwo ezinhle kakhulu. Akuyona nje i-powder eluhlaza yezinto ezithuthukisiwe ze-alumina ceramics ezifana nama-substrates wesifunda ahlanganisiwe, amagugu okwenziwa, amathuluzi okusika, amathambo okwenziwa, njll., kodwa futhi ingasetshenziswa njengesithwali se-phosphor, izinto eziphambili zokuphikisa, izinto zokugaya ezikhethekile, njll

Ukusetshenziswa kwe-α-alumina kuma-ceramics asebenzayo

I-ceramics esebenzayobheka izitsha zobumba ezithuthukisiwe ezisebenzisa izakhiwo zazo zikagesi, kazibuthe, i-acoustic, i-optical, ezishisayo nezinye noma imiphumela yazo yokuhlanganisa ukuze kuzuzwe umsebenzi othile. Zinezinto eziningi zikagesi ezifana nokufaka ugesi, i-dielectric, i-piezoelectric, i-thermoelectric, i-semiconductor, i-ion conductivity kanye ne-superconductivity, ngakho-ke zinemisebenzi eminingi kanye nezicelo ezibanzi kakhulu. Njengamanje, okuyinhloko okuye kwasetshenziswa ngendlela engokoqobo ngezinga elikhulu ama-ceramics afaka ama-ceramics ama-substrates wesifunda esihlanganisiwe kanye nokupakishwa, i-automotive spark plug insulating ceramics, i-capacitor dielectric ceramics esetshenziswa kabanzi kumathelevishini namarekhodi wevidiyo, i-piezoelectric ceramics esebenzisa okuningi kanye ne-ceramics ebucayi yezinzwa ezihlukahlukene. Ngaphezu kwalokho, zibuye zisetshenziselwe amashubhu akhipha ukukhanya kwesibani se-sodium enengcindezi ephezulu.

1. I-Spark plug insulating ceramics

I-Spark plug insulating ceramics okwamanje iwukuphela kwesicelo esikhulu kunazo zonke sezitsha zobumba ezinjinini. Ngenxa yokuthi i-alumina ine-insulation kagesi enhle kakhulu, amandla aphezulu emishini, ukumelana nengcindezi ephezulu kanye nokumelana nokushaqeka okushisayo, ama-alumina insulating spark plug asetshenziswa kabanzi emhlabeni. Izidingo ze-α-alumina zama-spark plug ama-micropowder e-alpha-alumina aphansi anesodium ephansi, lapho okuqukethwe kwe-sodium oxide kungu-≤0.05% futhi usayizi wezinhlayiyana omaphakathi ungu-325 mesh.

2. Ama-substrates wesifunda ahlanganisiwe nezinto zokupakisha

Ama-Ceramics asetshenziswa njengezinto ezingaphansi kwe-substrate nezinto zokupakisha ziphakeme kunepulasitiki kulezi zici ezilandelayo: ukumelana nokushisa okuphezulu, ukumelana nokugqwala kwamakhemikhali aphezulu, ukubekwa uphawu okuphezulu, ukuvimbela ukungena komswakama, akukho ukusebenza kabusha, futhi akukho ukungcoliswa kwe-silicon ye-ultra-pure semiconductor. Izakhiwo ze-α-alumina ezidingekayo kuma-substrates wesekethe edidiyelwe kanye nezinto zokupakisha yilezi: i-thermal expansion coefficient 7.0×10-6/℃, conductivity ezishisayo 20-30W/K · m (igumbi lokushisa), i-dielectric engaguquki 9-12 (IMHz), ukulahleka kwe-dielectric 3~10-4 (>101 MHz), ivolumu yokumelana nokumelana (I-10cm) , ivolumu yokumelana nokumelana ne-10cm.

Ngokusebenza okuphezulu nokuhlanganiswa okuphezulu kwamasekethe ahlanganisiwe, izidingo eziqinile zibekwe phambili kuma-substrates nezinto zokupakisha:

Njengoba ukukhiqizwa kokushisa kwe-chip kwanda, ukuqhutshwa kokushisa okuphezulu kuyadingeka.

Ngejubane eliphezulu lesici se-computing, i-dielectric constant ephansi iyadingeka.

I-coefficient yokwandisa okushisayo iyadingeka ukuze isondele ku-silicon. Lokhu kubeka izidingo eziphakeme ku-α-alumina, okungukuthi, ithuthuka ibheke ekuhlanzekeni okuphezulu nokucoleka.

3. Isibani esikhipha ukukhanya kwe-sodium esinengcindezi ephezulu

I-ceramics emihleezenziwe nge-high-purity ultrafine alumina njengezisetshenziswa zokusetshenziswa zinezici zokumelana nokushisa okuphezulu, ukumelana nokugqwala, ukufakwa kahle kwe-insulation, amandla aphezulu, njll., futhi ziyizinto ezinhle kakhulu ze-ceramic optical. I-polycrystalline esobala eyenziwe nge-alumina ehlanzekile enenani elincane le-magnesium oxide, i-iridium oxide noma izithasiselo ze-iridium oxide, futhi yenziwa umoya we-sintering kanye nokucindezela okushisayo, ingamelana nokugqwala komhwamuko we-sodium osezingeni eliphezulu futhi ingasetshenziswa njengezibani ezikhipha ukukhanya kwe-sodium ezinomfutho ophezulu osebenza kahle kakhulu.

Ukusetshenziswa kwe-α-alumina kuma-ceramics wesakhiwo

Njengezinto ze-inorganic biomedical, izinto ze-bioceramic azinayo imiphumela emibi enobuthi uma iqhathaniswa nezinto zensimbi nezinto ze-polymer, futhi zinokuvumelana okuhle kwe-biocompatibility kanye nokubola kokubola nezicubu zebhayoloji. Baye babazisa ngokwandayo abantu. Ucwaningo kanye nokusetshenziswa komtholampilo kwezinto ezisetshenziswayo ze-bioceramic kuthuthukile kusukela ekufakweni kabusha kwesikhashana nokugcwaliswa kuya ekufakweni okuhlala njalo nokuqinile, futhi kusuka ezintweni ezingasebenzi kahle zebhayoloji kuya ezintweni ezisebenzayo ngokwebhayoloji kanye nezinto eziyinhlanganisela yezigaba eziningi.

Eminyakeni yamuva, i-porousi-alumina ceramicsasetshenziselwe ukwenza amalunga okwenziwa amathambo, amalunga amadolo okwenziwa, amakhanda ezinsikazi zokwenziwa, amanye amathambo okwenziwa, izimpande zamazinyo okwenziwa, izikulufo zokulungisa amathambo, nokulungiswa kwekhone ngenxa yokungagugi kwamakhemikhali, ukumelana nokuguga, ukuzinza okuhle kwezinga lokushisa eliphezulu, kanye nezakhiwo zikagesi ezishisayo. Indlela yokulawula usayizi wembotshana ngesikhathi sokulungiswa kwezimbotshana zobumba ze-alumina iwukuxuba izinhlayiya ze-alumina ezinosayizi wezinhlayiyana ezihlukene, ukufaka igwebu, bese ufafaza ukomisa izinhlayiya. Amapuleti e-aluminium angaphinde afakwe i-anodized ukuze akhiqize izimbotshana zohlobo lwesiteshi esine-nano-scale microporous.